The process of making Chikankari has distinct steps and each step involves artisans with specific skills honed over many years. This process hasn’t altered much over the millennia. Some steps of the process are traditionally done by the male members of the community; however, the key step of stitchery or embroidery has always been the women’s domain. The beauty of this tradition lies also in the fact that it transcends religion or caste as both Hindus and Muslims of Awadh have an equal claim to its heritage and practice to this day.

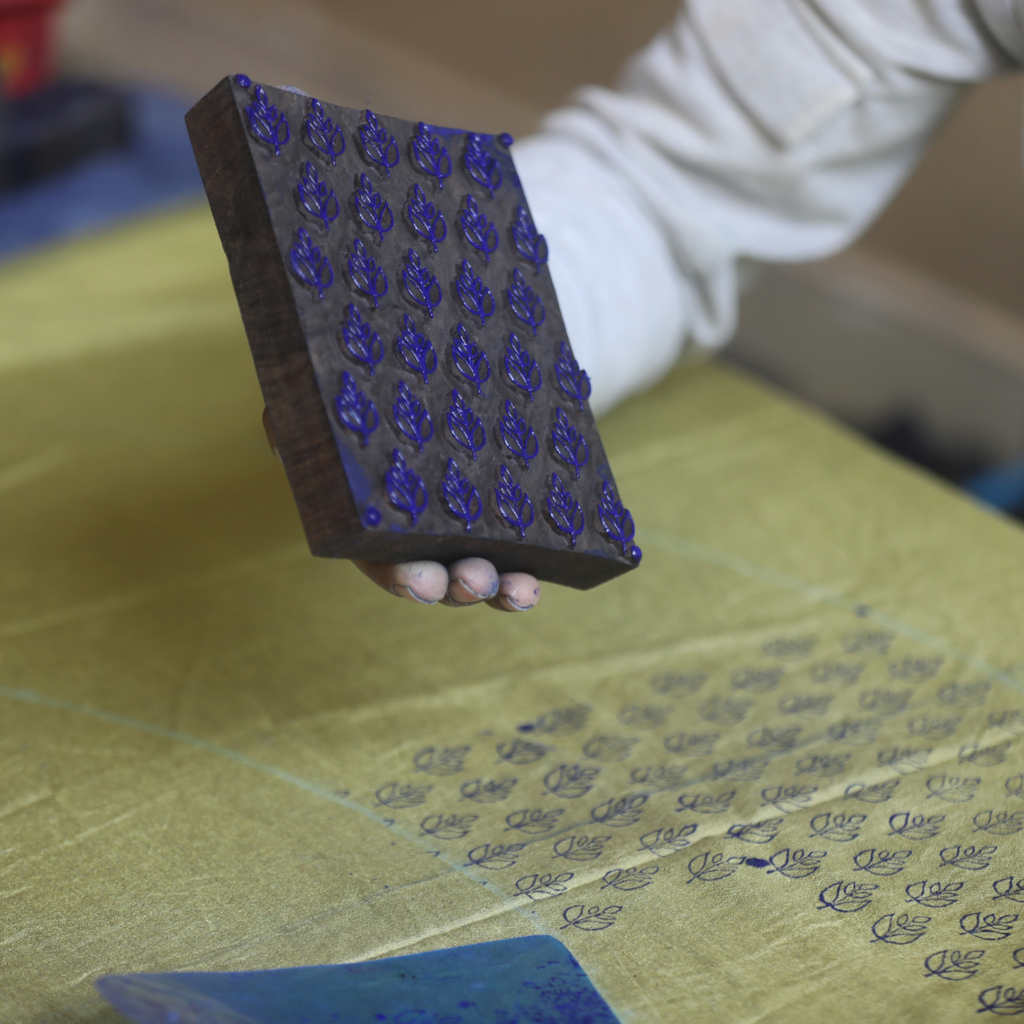

The chikankari story begins with tracing beautiful patterns of intricate designs on a block of wood. ‘Khaka’ or tracing style of wooden blocks is quite unique and by the pattern formation, a karigar can identify which embroidery technique will be best suited for the pattern.

Block makers or thappakars chisel the pattern meticulously on the block of wood, which is mostly ‘sheesham’ as it is termite resistant and doesn’t absorb moisture. After the blocks are carved, soaking them in oil is an integral process to avoid warping of the block, which may affect the design pattern. Gyan Bhai, with his years of experience in the craft, gave life to our designs by turning patterns into blocks.

Indigo dyeing is very unique to chikankari. Most of the blocks don't have handles on top. They are flat, so that karigar can easily stamp the design on the fabric. ‘Chappai’ or printing style of chikankari is different from other block printing techniques. Here, kargars have a low height bed with thick cushioning and they comfortably sit down on the floor for long hours. Munna Bhai is always kind with our experimenting with unique block designs, patiently stamping them on a piece of old newspaper first and then transferring it on the fabric.

Fine chikan is a skill of stitchery and accuracy of the work. The balance & combination of different stitches play a key role in the final outcome. The vastness of embroidery comes from more than 32 techniques. From flat pattern to embossed 3D effect and perforation, a simple pattern can be a combination of 3-4 stitches. Bakhiya or shadow work is the most commonly known stitch which creates an interesting pattern on both sides of the fabric. Jaali is like a mesh, reflecting lightness of touch. Saba and her team are our support system in the whole process. We see our imagination coming alive with their soulful work.

After the piece is embroidered, it goes for washing. Dhobi or washerman removes all the indigo dyed patterns, which is essential for karigar for embroidery but equally important to remove them completely so that the stitches are neatly visible and the fineness of the craft is not subdued.

Post washing, pieces go back to embroidery karigars for removing extra threads and giving last touches before sending them to tailoring units.

From procurement of fabrics to the last leg of stitching the finished product, chikankari is a story of multiple processes, seamlessly carried out by different karigars, working in sync. It's truly a legendary Lucknawi craft which should be preserved for coming generations.